Understanding the HM88 Series: Key Features and Benefits

The HM88 Series represents a groundbreaking development in manifold technology, specifically designed to streamline industrial processes. With precision engineering at its core, the HM88 offers reliability and efficiency for a wide range of applications, cementing its status as a preferred choice among industry professionals. When exploring options, hm88 provides comprehensive insights into the manifold’s design and functionalities that cater to various sectors.

What is the HM88 Series?

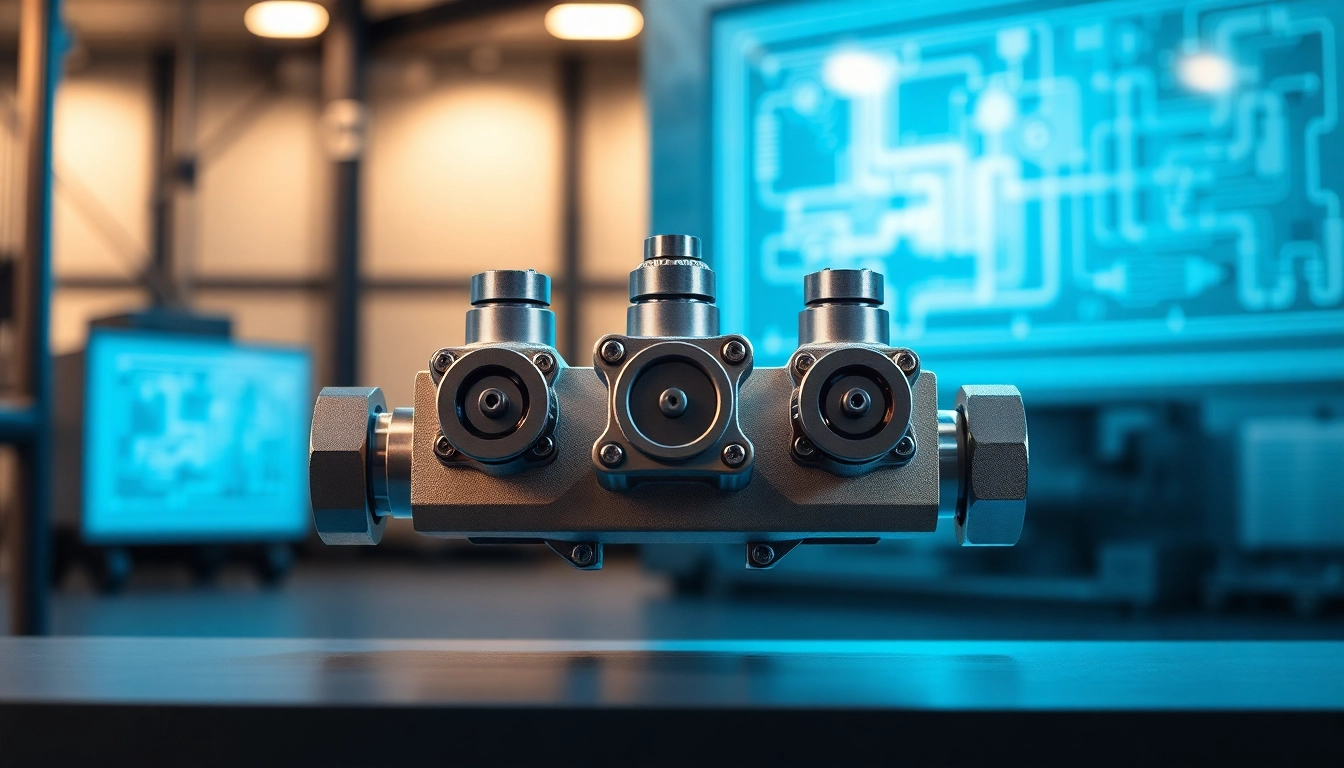

The HM88 Series is a robust range of three-valve direct mount manifolds that facilitate the direct attachment of differential pressure transmitters to orifice flanges. This series is integral to applications requiring accurate measurement of pressure in pipelines, ensuring optimal operational efficiency. The HM88’s design focuses on minimizing potential leak points and enhancing the ease of installation and maintenance, which is crucial in high-demand industrial environments.

Core Benefits of the HM88 Design

- Enhanced Accuracy: The HM88 Series provides superior accuracy in pressure measurement, essential for reliable data in critical applications.

- Reduced Complexity: With a direct mount design, the HM88 minimizes components, leading to simpler installations and reduced risk of errors.

- Durability: Engineered with high-quality materials, the HM88 is built to withstand harsh industrial conditions, ensuring longevity and consistent performance.

- Cost Efficiency: By reducing installation time and minimizing maintenance needs, the HM88 Series contributes to lower operational costs for businesses.

Comparative Analysis: HM88 vs Competitors

When comparing the HM88 Series to its competitors, several key differentiators emerge. Many alternatives may offer similar features, yet the precision and durability of the HM88 Series often outweigh those options. For instance, while competitors may have lower initial costs, they frequently entail higher maintenance and replacement expenses over time. The HM88, on the other hand, is designed for longevity, thus proving to be more cost-effective in the long run.

Applications of HM88 Series in Various Industries

The versatility of the HM88 Series allows it to be utilized across multiple sectors, making it a valuable asset in various industrial applications. From manufacturing to energy, the manifold’s impact is profound, improving safety and efficiency.

Industrial Automation and Control

In the realm of industrial automation, the HM88 Series plays a crucial role in maintaining control systems that require precise pressure measurements. It is integral to the operation of automated processes, ensuring that machinery operates within safe pressure limits. The reliability of the HM88 minimizes downtime caused by faulty readings, enabling continuous operation.

Oil and Gas Sector Utilization

In the oil and gas industry, accurate pressure measurements are essential for safety and efficiency. The HM88 Series is used extensively in extraction and refining processes, where monitoring pressure is critical for preventing leaks and ensuring compliance with safety regulations. Its robust design is particularly advantageous in the harsh environments typically encountered in this sector.

Benefits in Water Treatment Processes

The HM88 Series also finds its applications in water treatment facilities, where it aids in monitoring and controlling the pressure of water flow throughout the treatment process. This ensures optimal performance in filtration and chemical dosing systems, contributing to safer and cleaner water supply for communities.

Installation Best Practices for HM88 Series Manifolds

To maximize the performance of the HM88 Series, proper installation is paramount. Adhering to best practices can significantly reduce the risk of operational issues and enhance the longevity of the equipment.

Preparation Steps Before Installation

- Gather all necessary tools and materials.

- Review the manufacturer’s installation instructions carefully.

- Inspect the manifold and components for any signs of damage before installation.

- Ensure compatibility with existing systems to avoid integration issues.

Common Installation Mistakes to Avoid

Common mistakes during installation can lead to performance issues. These include:

- Improper alignment of the manifold with the transmitter or orifice flange.

- Neglecting to tighten fittings adequately, risking leaks.

- Overlooking pressure testing after installation to confirm integrity.

Step-by-Step Installation Guide

- Begin by securing the manifold to the orifice flange, ensuring it is aligned correctly.

- Carefully tighten all fittings, avoiding over-torquing which may damage components.

- Connect the differential pressure transmitter to the manifold, following the wiring schematic.

- Conduct a pressure test to check for leaks and ensure all connections are secure.

- Document the installation for future reference and maintenance planning.

Maintenance Tips for Prolonging HM88 Series Performance

Routine maintenance is essential for the optimal functioning of the HM88 Series. Regular checks can help identify and mitigate potential issues before they escalate.

Routine Maintenance Checks

- Inspect the manifold for signs of wear or corrosion.

- Check for leaks and ensure all connections are tight.

- Test the pressure readings periodically to ensure they remain within acceptable ranges.

Troubleshooting Common Issues

If discrepancies in pressure readings occur, it may indicate issues such as:

- Clogged or damaged sensors that require replacement.

- Incorrect installation leading to misalignment of components.

- Environmental factors, such as temperature fluctuations, affecting performance.

Upgrades and Retrofits for Enhanced Efficiency

As technology evolves, so too should equipment. Retrofitting existing systems with the latest HM88 Series updates can enhance functionality. Consider integrating advanced digital sensors or automated monitoring systems to improve data accuracy and operational efficiency.

Future Trends in Manifold Technologies Beyond 2025

The landscape of manifold technologies is ever-evolving. Anticipating future trends allows companies to stay ahead of the curve, adopting innovations that enhance productivity and efficiency.

Innovations in Manifold Engineering

Future developments will likely include the integration of smart technology for real-time monitoring and data analysis. Machine learning could be employed to predict potential failures based on historical data, enabling proactive maintenance strategies.

Market Predictions for Industrial Solutions

As industries continue to evolve, the demand for more efficient manifold solutions is expected to rise. By 2025, the market could see a significant shift toward eco-friendly materials and designs that minimize environmental impact while enhancing performance.

Emerging Technologies Impacting HM88 Design

Advancements in materials science, including the development of lightweight, high-strength composites, may further enhance the HM88’s capabilities. Additionally, the incorporation of IoT connectivity will allow for seamless data exchange between manifolds and control systems, optimizing operations across various sectors.